“The goal is to shift the focus of producers from just growing a high-performing animal to producing a predictable, top-quality carcass,” says MasterHand Milling owner Dusty Turner. The company recently released the latest round of data from its research trials conducted in partnership with Oklahoma State University studying the impacts of feeding distillers grain cubes.

Dependable Data

The grazing trials have been ongoing since 2019 and Turner says the trends from that data are consistent year after year. Complete data from these

“We’ve seen identical, repeatable performance with these cubes,” Turner said. “Over and over the added gains and returns show it’s a no-brainer to feed extruded DDG cubes to cattle on grass.”

Beginning in 2020, the research team partnered with Buffalo Feeders to retain the cattle off grass and track performance through the feedyard. General Manager Tom Fanning said he was impressed by the first round of data collected.

“Cattle fed MasterHand Milling range cubes started faster, gained better, had an improved dry matter conversion, and had a superior carcass compared to control pens that were not fed the range cubes,” he said. “It looks like this is truly a value-added product you can use to improve the performance of your cattle being retained in the feedyard.”

The latest data tracks cattle fed on grass at three different Oklahoma locations through the summer 2021 season and fed out in early 2022.

Driving Performance

“The main objective with these feedlot trials is to dial in on the optimum feeding rate on grass that drives the best possible performance in the feedyard,” Turner said.

Each research station had a slightly different trial design, each testing various feeding rates and conditions. The cattle for each trial also varied significantly in type, with some locations feeding large-framed Brangus cross calves and another location using straight Hereford steers.

Turner said the key takeaway from all the trials was finding a point of diminishing return when feeding DDG cubes on grass.

“There is a sweet spot around 2 to 3 pounds per head per day that will optimize returns on grass and create a larger, leaner animal that will both convert in the feedyard and perform on the grid,” he said.

Trial Design & Locations

Some quick background before we tackle the data. MasterHand Milling first partnered with the OSU Cooperate Extension Service and Dr. Paul Beck in 2019 by donating feed to the research projects being conducted by graduate students studying ruminant nutrition. The trials are conducted by the student research teams including cattle care, data collection and reporting.

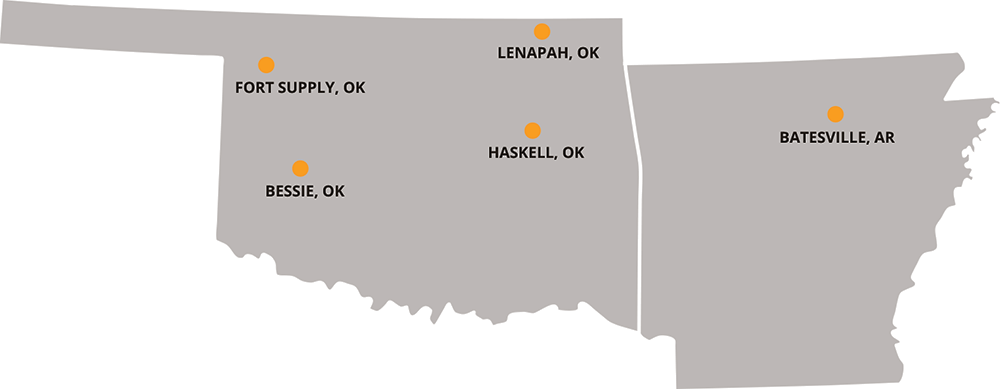

The primary locations for these trials are in Bessie, Fort Supply and Haskell, Oklahoma. Additional studies have also been conducted in Lenapah, Oklahoma and Batesville, Arkansas. For the sake of today’s discussion, we’ll focus on the three primary research sites.

Give And Take

According to Turner, cattle fed 2 pounds per head per day on grass had higher average daily gain, had better conversion rates, finished heavier and had a higher percent Choice than cattle fed at higher rates (i.e., 4-6 pounds per head per day). Those cattle fed 4 pounds or more per head per day on grass tended to finish quicker at lower payweights with more yield grade 4s.

As for cattle not fed on grass, some treatment groups showed moderate compensatory gain in the feedyard, but all control groups were on feed longer with lighter payweights. They had lower in-weights, required more days on feed to finish and had similar or lower average daily gains compared to fed cattle.

“There’s always a give and take in the feedyard,” Turner said. “If you feed them longer, your feed conversion is going to get worse, but the grid premium could get better. What we’re doing with this cube is making these cattle more predictable by setting them up for optimum gain and conversion which leads to optimum grid performance.”

Trial 1 – Bessie, Oklahoma

The 2021 grazing trial at Bessie was a new design testing supplementation rate through the summer. Three treatment groups included an unsupplemented control, a low supplement rate at 2 lbs. per head per day and a high supplement rate at 4 lbs. per head per day.

The low supplementation cattle gained 0.67 lbs. per head more on average than the control, while the higher supplementation cattle gained an additional 0.92 over the control.

After factoring in all input costs including cattle purchase, pasture rent, processing, mineral and feed, cost of gains for the control, low supplement and high supplement groups were $0.73, $0.70 and $0.82 respectively. An estimated breakeven price per pound was calculated for each group with the control group at $1.46, low supplement at $1.36 and high supplement at $1.37.

This data shows the potential value to be added for producers who invest in a distillers cube summer feed program. At 2 lbs. per head per day, the additional gain was able to reduce the breakeven price, regardless of the added feed cost per head.

Preliminary feedlot data has been collected on the Bessie cattle at time of reimplant. Fed cattle went into the feedlot weighing 100+ lbs. more than the control cattle. After 90 days on feed, the heavier fed cattle are maintaining a higher average daily gain than the lighter cattle with roughly the same feed conversion rate.

Trial 2 – Haskell, Oklahoma

The 2021 study at Haskell was the second year of a project studying the impacts of pasture fertilization and feed supplementation on cattle gains. The cattle were broken into three treatment groups: 1) no supplement control, 2) Fertilized pasture and fed 2.75 lbs. per head per day, and 3) Unfertilized pasture and fed 5.9 lbs. per head per day.

As expected, the fed cattle outperformed unfed cattle with Group 2 gaining an average of 2.44 lbs. over the 1.89 lb. average of the control. Group 3 at the higher supplementation rate average 2.66 lbs. Both Group 2 and 3 gained over 3 lbs. for the first half of the season.

After all input costs, not including pasture fertilization, cost of gain was $0.48, $0.62, and $0.83 respectively for Groups 1, 2 and 3. Breakeven prices per pound came to $1.30, $1.32 and $1.39. These values indicate a point of diminishing return when feeding at rates above 2-3 lbs. per head.

Early feedlot data from this trial are very interesting at they pertain to the widely accepted theory that feeding cattle before sending them to the feedyard negatively impacts feedyard performance. As in the Bessie trial, fed cattle weighed more going in and will take fewer days on feed to finish.

At 90 days on feed, control group cattle were gaining 3.86 lbs., while low supplement cattle were at 3.93 and high supplement cattle were gaining 4.38. Fed cattle had better dry matter conversion and a lower cost of gain than the control group.

Trial 3 – Fort Supply, Oklahoma

Fort Supply also had a new trial design in 2021 similar to the set up at Bessie. This trial split into four groups: 1) no supplement control, 2) fed 2 lbs. per day, 3) fed 4 lbs. per day, and 4) fed 6 lbs. per day.

As in previous studies, fed cattle gained more with increased supplementation. Average daily gains for the summer were 1.51 lbs. for the control group, 2.17 for Group 2, 2.23 for Group 3 and 2.34 for Group 4. Cattle maintained a steady gain through the season.

Cost of gain values were calculated at $0.63, $0.65, $0.82 and $0.93 respectively. The lowest breakeven cost was in Group 2 at $1.26, indicating the same point of diminishing return at 2-3 lbs. as seen in other trials.

Reimplant data showed a decrease in daily gains and higher dry matter conversion on cattle fed at the higher rates on grass. This differs from findings in previous studies. The difference in performance is likely due to the types of cattle used in each trial. At Bessie and Haskell, the cattle were high quality Ultrablack (Brangus X Angus) steers purchased from a registered Brangus operation. The Fort Supply cattle consisted of plainer, sale barn type steers. It makes sense to generally expect cattle with better genetic potential to maintain higher performance than animals without that same genetic backing.